“Making microLED displays is extremely difficult, extremely expensive, and has low yield.” That’s how Digital Trends’ Caleb Denison put it when he explained why we probably won’t see a consumer-level microLED television in 2025. However, what about smaller microLED displays, such as those suitable for tablets, laptops, smartwatches, or even smart rings?

Technology company Smartkem has a solution to the high manufacturing costs involved with microLED displays and is working with display maker AUO on a transparent, rollable microLED that, although modestly sized now, could be the start of something much bigger. Digital Trends spoke to Smartkem’s chairman and CEO, Ian Jenks, about its breakthrough and what it may mean for mobile.

Why are microLED displays so expensive?

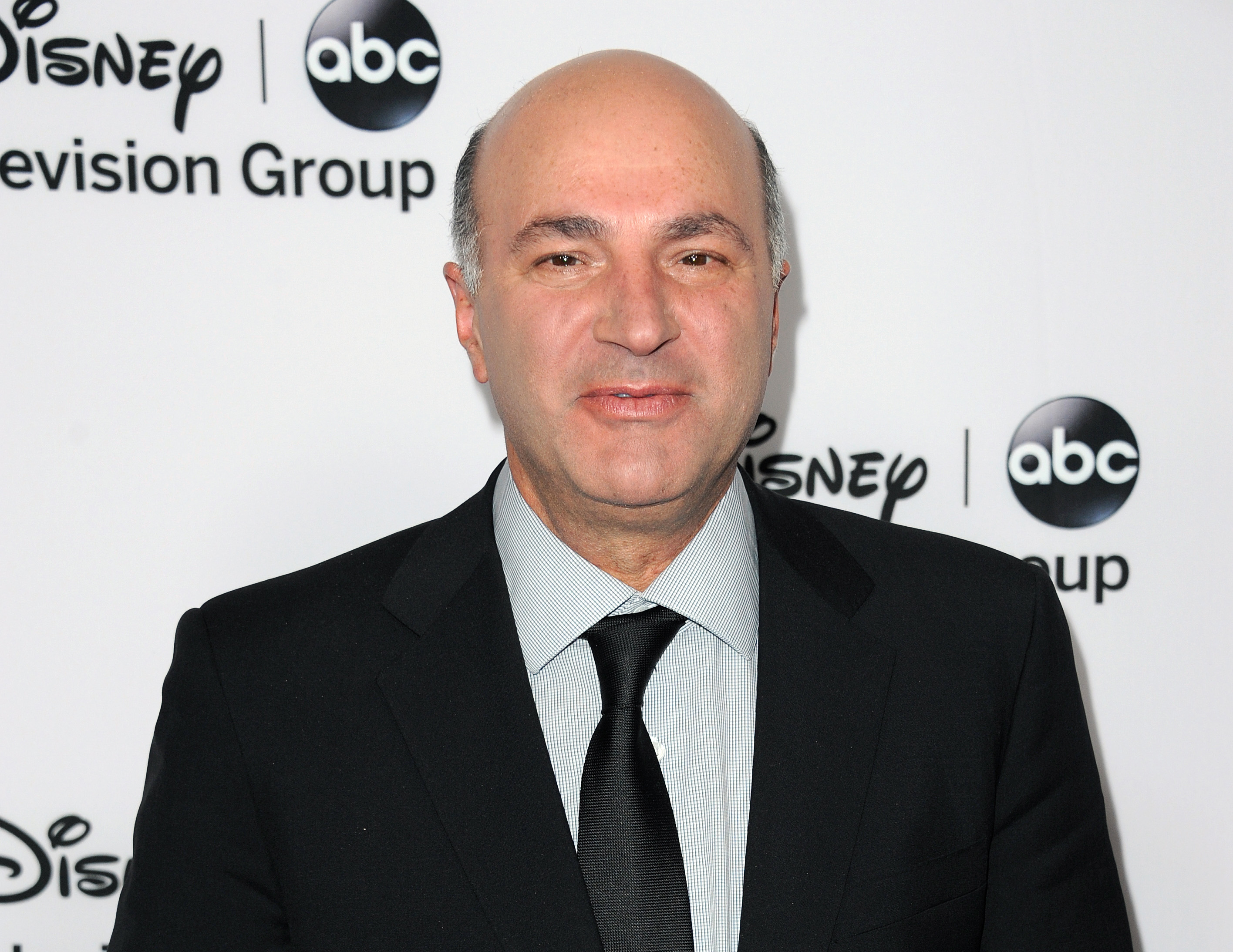

Ian Jenks, Smartkem chairman and CEO Smartkem

Ian Jenks, Smartkem chairman and CEO Smartkem“MicroLEDs are small and very efficient, and you need one red, one green, and one blue to make a pixel. What’s great about them is it’s a direct emissive, so it’s shining the light, more like an OLED than an LCD. It’s much brighter and has a wider color gamut than any other display technology, so when we see a microLED display, it pops. That’s what all the fuss is about,” Jenks explained.

Unfortunately, microLED displays are very hard to make, but Smartkem’s unique transistor technology may help display manufacturers produce microLED displays more efficiently and, in turn, make them more commercially viable.

“For a 42-inch TV, you need 25 million microLEDs,” Jenks said. This panel needs to be assembled like any other display, complete with a transistor, and tens of millions of connections need to be laser-welded together down to micron-level accuracy. MicroLED displays are tested once assembled, and should there be dead pixels or other problems, the value has already been added in and the resulting cost of potentially scrapping the panel is very high.

“That’s why you pay so much for a microLED display today,” Jenks said. For reference, Samsung introduced a $110,000, 89-inch microLED television earlier this year. Having covered how it all works now, Jenks then explained what Smartkem does differently.

Lower temperatures, higher yields

A demonstration of Smartkem’s Organic Thin Film Transistor (OTFT) technology Smartkem

A demonstration of Smartkem’s Organic Thin Film Transistor (OTFT) technology Smartkem“What we do that’s different is we take the sheet of microLEDs and we make liquid polymer transistors, not silicon, and that means they come in a liquid and you can pour them, in layers, using photolithographic accuracy to align them up,” Jenks said. “You then spray metal over the top of tiny holes made in the first layer to connect them all up.

“All silicon-based transistors are processed at high temperatures, and this limits what you can process them on. We cure our polymers with ultraviolet light and it sets them solid, and this opens up a whole new world of substrates you can use, including ones that are totally transparent.”

Smartkem’s manufacturing process enables the microLEDs to be connected and tested prior to completion, increasing the yield. The process is the result of 15 years of research into organic transistors and an $80 million investment.

What’s exciting is the process is already on its way to a production line. Smartkem worked with the Industrial Technology Research Institute (ITRI) in Taiwan on a prototype production line making transistor sheets for tablet-sized displays. Subsequently, optoelectronics company AUO in Taiwan approached Smartkem to use its technology to make a 12.7-inch, tablet-sized, flexible, transparent screen together.

“We’ve started the process,” Jenks confirmed, and he expects the results to arrive in a couple of years’ time.

Big potential for small devices

Smartkem

SmartkemIf the microLED displays made using Smartkem’s manufacturing process are not TV-sized, what could they be used for? Jenks indicated AUO would like to use the flexible, transparent microLED displays on a “notebook” device, but it’s not clear exactly what form this would take. However, he envisaged a time when laptops will have transparent displays, opening up visual communication between people when they are placed on a desk in offices, conferences, and in stores. It’s similar to how Samsung demonstrated its transparent microLED screens.

He continued to expand on how small-scale microLED screens may be used in products we can buy.

“I think that in the next two or three years we will have transparent tablets and notebooks, and I think [Smartkem] will enable that. I think you’ll have a transparent band on your wrist that’s quite soft and flexible too, and I also see cool-looking watches with transparent plastic or glass “dials” where the display only appears when you turn your wrist.”

Jenks pointed to the Oura Ring on his finger and talked about how he’d like a smart ring to have a tiny display to send emojis to loved ones or show other small snippets of information. “I’d like it to have a little display,” he said. “But it’s got to be flexible, robust, and very low power. I think the only way you can do that is with these little microLEDs.”

Beyond these applications, we’ve seen a concept rollable smartphone called the Rizr from Motorola recently, and both Huawei and Samsung are experimenting with complicated tri-folding smartphones. A robust, flexible screen is essential for these devices, and by using a microLED display, manufacturers wouldn’t have to compromise on visual quality.

What about TVs?

114-inch Samsung microLED TV Phil Nickinson / Digital Trends

114-inch Samsung microLED TV Phil Nickinson / Digital TrendsSmartkem’s manufacturing process is paving the way to AUO’s world-first rollable, transparent microLED display, and it’ll be modestly sized for devices like tablets and laptops, with potential for wearables and other mobile products in the future. But what about televisions, where the benefits of microLED have already been tantalizingly shown off by brands like Samsung?

Jenks is quoted as saying, “Smartkem’s technology has the potential to take today’s microLED TVs from high-end market prices of $100,000 down to mass market prices,” in a company press release, but what does that really mean?

“When you get into modest volumes, [the costs] are comparable to OLED TVs today. It’s the difference between exotic and consumer. If you can solve manufacturing problems, yields go up and the price goes down,” he told Digital Trends.

While microLED tablets, wearables, and TVs are the most exciting applications to us, Jenks actually sees microLED displays gaining traction in another space before we get there.

Near-future microLED displays

Smartkem

Smartkem“Where do I really think microLEDs will take off? Signage. Huge signage,” Jenks told us. “These displays are mostly made with mini-LEDs today, and they generate a lot of heat. You can replace those mini-LEDs with multiple microLEDs, and it has a dramatic effect on power consumption.”

It just so happens that these same power efficiency benefits that will appeal to companies making signage will also make microLEDs suitable for automotive use.

“I think it will be those applications that will drive the price of microLEDs down while we’re all working on transparent, flexible displays for TVs, tablets, or watches,” Jenks said.

The 12.7-inch microLED display being produced by AUO using Smartkem’s unique manufacturing technology is the first step toward a host of exciting microLED-equipped products.

![Hands-on: Gemini on Google TV is faster, better, and more futuristic [Video]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/01/DSC6693.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

English (US) ·

English (US) ·